Plasma cutting is used in many industries.

Origin of Plasma Cutter

Plasma is an ionized, ionized gas that can provide a lot of energy. This gas is able to emit electrons from the atoms, and allow electrons and ions coexist. The plasma forms when the gas is heated too much. The fast-moving ions are broken down and formed a lot of energy. Strong force is what creates the great cutting force. For more information, see this.

It was constructed during World War II. This machine is used to cut metal welders. They inhale the most irritating gases. These devices are often called plasma flashlights. Plasma cutters are capable of cutting solid metals in a matter of minutes.

Plasma cutters used in different industries

It is a tool that can be used by small businesses. They are made from hard metals such as silver, aluminum and copper. They can also be used to cut and shape metals. They are also used in machine-making factories.

This machine is used by many companies every day. It can be difficult to build heavy machinery and airplanes without a lot of effort. These tools are also used by the aviation industry. There are several industries that make use of them, including plumbing. Artists often use this tool to create metal and sculpture.

AI is one of the biggest tech news. We are still only in the early days of the development of AI. As the technology becomes more sophisticated, it will be applied to further develop tech-based tools, such as training machines to recognize patterns, and then act upon what it has detected. It can develop your best business times idea and you can succeed in your life goal.

Plasma cutting function

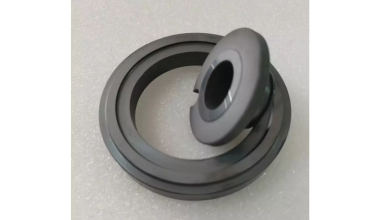

The cone’s mouth emits many gases such as nitrogen, oxygen, and argon. The electrode pushes electricity into the gases through a process called “ionization”. All the atoms in the gas will revolve around the catalyst due to ionization. They create plasma by separating electrons from the nucleus. It is sent in its most active state. It is the work that generates the most energy and can be used in advanced industrial machinery.

How do you choose a plasma bolt?

You must first determine what your work requires and the type of work you are doing. For this purpose, a plasma cutter is required. You can choose the car that you need for your business, and skip the more powerful model. While you may need to spend more for a powerful tool, you can still meet your business needs with a smaller device. You should be careful when purchasing such a vehicle. A more powerful plasma cutter is available if your business requires regular plasma cutting. They can light the central flame with the latest technology, and they are relatively inexpensive.

The most important tools in the metal fabrication industry are plasma cutters and flashlights. It is highly efficient and precise in metal cutting. It cuts metal with precision and accuracy by using high temperatures. It was developed in World War II. The features of this useful tool have greatly improved with the advances in science and technology.

Plasma cutters are different because they use plasma gas for cutting metal. The cutter emits gas from a narrow key. This can be either oxygen, nitrogen, or air. This fuel is heated to plasma at high temperatures and can be used for metal cutting. The metal is protected from corrosion by another gas.

Other than this metal cutting tool there are high-resolution plasma and laser options. Laser cutters can be more costly, but they are also much easier to use. Laser cutters can achieve greater accuracy, but they are still considered more precise.

Metal cutting tools can be used in many different ways. It is used by the automotive industry to cut and shape parts. It can also be used to cut large metal sheets in heavy industry. CNC machines use plasma cutters to attain high precision. Workers can automate the shaping and cutting of metal using CNC machines by using a computer.

It is widely used by artisans for cutting metal. Because it can cut fine details with small shifts, it is also popular.

These cutters have the greatest advantage in precision and accuracy. It is therefore widely used in the metallurgy sector.

This cutting tool has another advantage: the metal surface remains cool after cutting. This prevents paint damage and damage, which can be common with other metal cutters.